Kushandiswa kweSMT kumashure-kumagumo cell line mu3C zvemagetsi indasitiri

GREEN iNational High-Tech Enterprise yakatsaurirwa kuR&D uye kugadzira otomatiki emagetsi gungano uye semiconductor kurongedza & yekuyedza michina.

Kushandira vatungamiriri veindasitiri vakaita seBYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, uye makumi maviri+ mamwe mabhizinesi eFortune Global 500. Wako waunovimba naye kune epamberi kugadzira mhinduro.

Surface Mount Technology (SMT) ndiyo musimboti maitiro mukugadzira zvemagetsi zvemazuva ano, kunyanya kuindasitiri ye3C (kombuta, kutaurirana, zvemagetsi zvevatengi). Inokwirisa zvisingatungamiri / zvipfupi-zvinotungamira zvikamu (SMDs) zvakananga paPCB nzvimbo, zvichiita kuti hukuru-density, miniaturized, lightweight, high-reliability, uye kugadzirwa kwepamusoro-soro.Nzira yeSMT inoshandiswa sei mumakambani emagetsi e3C, uye midziyo inokosha uye matanho ekugadzirisa muSMT back-end cell line.

□ 3C zvigadzirwa zvemagetsi (zvakadai sema smartphones, mahwendefa, malaptop, smartwatches, mahedhifoni, ma routers, nezvimwewo) inoda yakanyanyisa miniaturization, slim profiles, kuita kwepamusoro,uye nokukurumidza

iteration.SMT mitsetse inoshanda sepakati pekugadzira chikuva inogadzirisa izvo zvinodiwa.

□ Kuwana Yakanyanya Miniaturization uye Lightweighting:

SMT inogonesa kurongeka kwakaomarara kwezvidiki-zvikamu (semuenzaniso, 0201, 01005, kana madiki resistors/capacitor; fine-pitch BGA/CSP chips) paPCBs, ichideredza zvakanyanya bhodhi redunhu.

tsoka, vhoriyamu yemudziyo wese, uye uremu - yakakosha inogonesa michina inotakurika senge ma smartphones.

□ Kugonesa High-Density Interconnect & High Performance:

Zvigadzirwa zvemazuva ano zve3C zvinoda kushanda kwakaoma, zvinoda high-density interconnect (HDI) PCBs uye multilayer intricate routing. SMT's chaiyo yekuisa kugona inoumba iyo

hwaro hwekubatana kwakavimbika kweakakwira-density wiring uye epamberi machipisi (semuenzaniso, processors, memory modules, RF zvikamu), kuve nechokwadi chekuita kwakanaka kwechigadzirwa.

□ Kuwedzera Kubudirira Kwekugadzira & Kuderedza Mari:

Mitsetse yeSMT inopa yakakwira otomatiki (kudhinda, kuisa, kuyerera, kuongorora), yekupedzisira-inokurumidza throughput (semuenzaniso, mitengo yekuisa inodarika 100,000 CPH), uye kushoma kupindira kwemaoko. Izvi

inovimbisa kuenderana kwakasiyana, kukwira kwegoho, uye inoderedza zvakanyanya mutengo we-uniti mukugadzirwa kwakawanda-kunyatsoenderana ne3C zvigadzirwa'zvinoda zvekukurumidza-ku-musika uye

mitengo yemakwikwi.

□ Kuve nechokwadi cheKuvimbika kweChigadzirwa & Hunhu:

Yepamberi SMT maitiro-kusanganisira kunyatso dhinda, yakakwirira-chaiyo kuiswa, inodzorwa reflow profiling, uye yakasimba inline yekuongorora-inovimbisa solder kubatana kuwirirana uye

kuvimbika. Izvi zvinoderedza zvakanyanya kuremara senge kutonhora majoini, bhiriji, uye chikamu chemisalignment, kusangana ne 3C zvigadzirwa 'zvakaomesesa kushanda kugadzikana zvinodiwa muhasha.

nharaunda (semuenzaniso, vibration, thermal cycling).

□ Kuchinjira kune Rapid Chigadzirwa Iteration:

Kubatanidzwa kweFlexible Manufacturing System (FMS) nheyo inogonesa mitsetse yeSMT kuti ishanduke nekukurumidza pakati pemhando dzechigadzirwa, ichipindura zvine simba kune inokurumidza kubuda.

zvinodiwa zvemusika we3C.

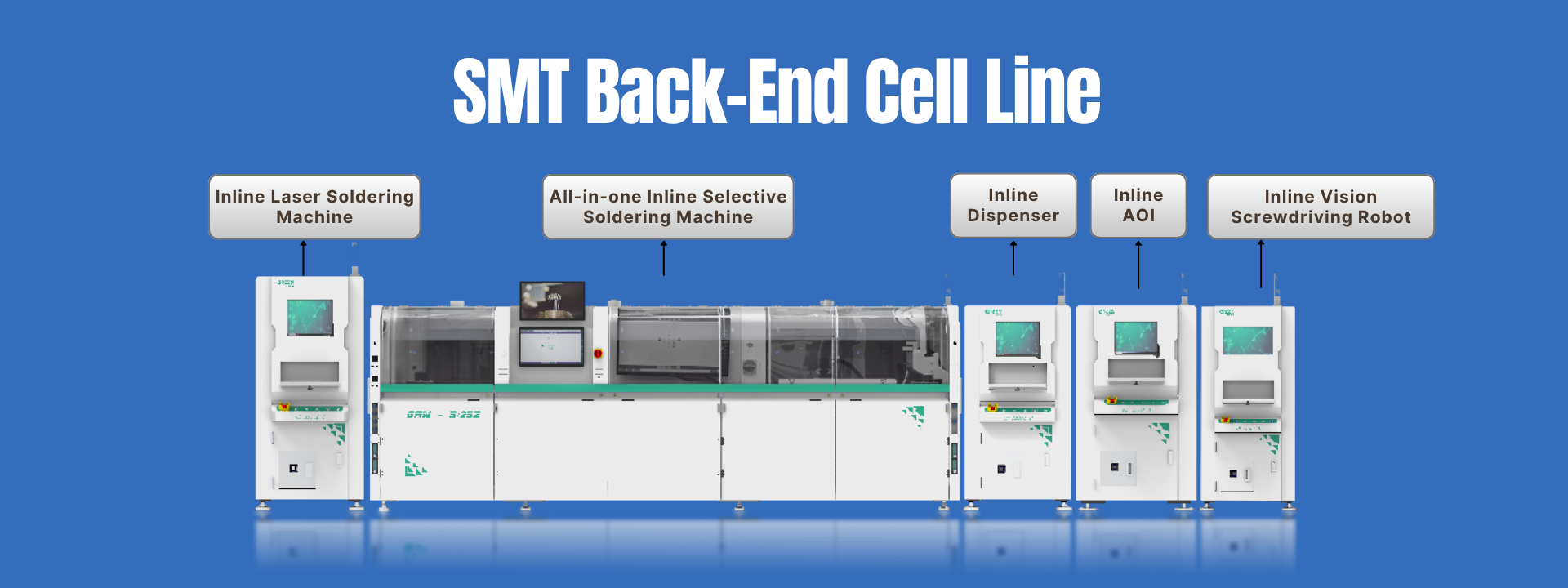

Laser Soldering

Inogonesa kunyatsoita tembiricha-inodzorwa solder kudzivirira kukuvara kune thermosensitive zvikamu. Inoshandisa isiri-yekubata gadziriso inobvisa kushushikana kwemechani, kudzivirira chikamu chekutamisa kana PCB deformation-yakagadziridzwa kune yakakombama / isina kujairika nzvimbo.

Sarudza Wave Soldering

MaPCB ane vanhu vanopinda muovheni reflow, uko inodzorwa tembiricha mbiri (preheating, soaking, reflow, kutonhora) inonyungudutsa solder paste. Izvi zvinogonesa kunyorova kwemapedhi uye chikamu chinotungamira, kugadzira yakavimbika metallurgical bonds (solder majoini), inoteverwa nekusimba pakutonhora. Tembiricha curve manejimendi yakakosha kune weld mhando uye kuvimbika kwenguva refu.

Yakazara-Automatic High-Speed In-Line Dispensing

MaPCB ane vanhu vanopinda muovheni reflow, uko inodzorwa tembiricha mbiri (preheating, soaking, reflow, kutonhora) inonyungudutsa solder paste. Izvi zvinogonesa kunyorova kwemapedhi uye chikamu chinotungamira, kugadzira yakavimbika metallurgical bonds (solder majoini), inoteverwa nekusimba pakutonhora. Tembiricha curve manejimendi yakakosha kune weld mhando uye kuvimbika kwenguva refu.

AOI Machine

Post-Reflow AOI Kuongorora:

Mushure mekutengesa patsva, masisitimu eAOI (Automated Optical Inspection) anoshandisa makamera ane chigadziriso chepamusoro uye software yekugadzira mifananidzo kuti iongorore otomatiki mhando yejoints paPCBs.

Izvi zvinosanganisira kuona kukanganisa kwakadai se:Solder Defects: Kusakwana / kuwandisa solder, majoini anotonhora, bhiriji.Component Defects: Misalignment, zvisipo zvikamu, zvisizvo zvikamu, reversed polarity, tombstone.

Seyakakosha yemhando yekudzora node mumitsara yeSMT, AOI inova nechokwadi chekugadzira kuvimbika.

Vision-inotungamirirwa Inline Screwing Machine

Mukati meSMT (Surface Mount Technology) mitsara, iyi hurongwa hunoshanda sechigadzirwa chemashure, kuchengetedza zvikamu zvakakura kana zvigadziro zvePCBs-zvakadai semasinki ekupisa, zvibatanidza, zvigadziro zveimba, nezvimwewo. Inosanganisira kudya kwemagetsi uye kururamisa torque control, apo inoona kukanganisa kunosanganisira screws yakapotsa, cross-threaded fasten, uye threaded threaded fasten.