Kushandisa muSemiconductor Indasitiri

GREEN iNational High-Tech Enterprise yakatsaurirwa kuR&D uye kugadzira otomatiki emagetsi gungano uye semiconductor kurongedza & yekuyedza michina. Kushandira vatungamiriri veindasitiri vakaita seBYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, uye makumi maviri+ mamwe mabhizinesi eFortune Global 500. Wako waunovimba naye kune epamberi kugadzira mhinduro.

Bonding machines inogonesa micro-interconnects nemadhayamita ewaya, kuve nechokwadi chekuvimbika kwechiratidzo; formic acid vacuum soldering inoumba majoini akavimbika pasi peokisijeni yemukati <10ppm, kudzivirira kutadza kweoxidation mu-high-density packaging; AOI inobata micron-level defects. Iyi synergy inovimbisa> 99.95% yepamusoro yekurongedza goho, kusangana nekunyanyisa kuyedzwa zvinodiwa zve5G/AI machipisi.

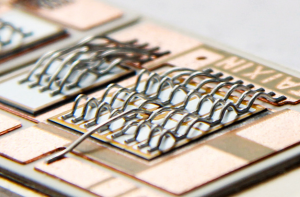

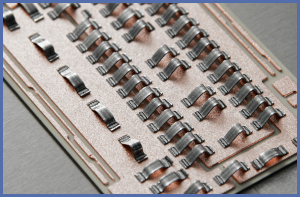

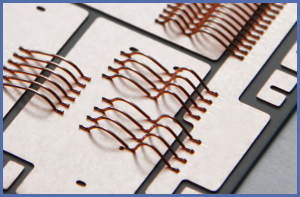

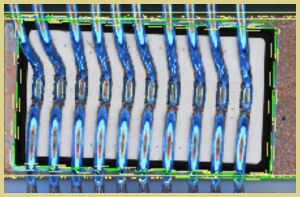

Ultrasonic Wire Bonder

Inokwanisa kusunga 100 μm–500 μm aluminiyamu waya, 200 μm–500 μm waya yemhangura, maribhoni ealuminium anosvika 2000 μm yakafara uye 300 μm mukobvu, pamwe chete nemarabhoni emhangura.

Rwendo rwekufamba: 300 mm × 300 mm, 300 mm × 800 mm (customizable), ine kudzokorora <±3 μm

Rwendo rwekufamba: 100 mm × 100 mm, nekudzokorora <± 3 μm

Chii chinonzi Wire Bonding Technology?

Wire bonding inzira yekubatanidza yemicroelectronic inoshandiswa kubatanidza semiconductor zvishandiso pakurongedza kwavo kana substrates. Seimwe yeanonyanya kukosha matekinoroji muindasitiri yesemiconductor, inogonesa chip kupindirana nemasekete ekunze mumidziyo yemagetsi.

Bonding Wire Materials

1. Aluminium (Al)

Superior magetsi conductivity vs. goridhe, inodhura-inoshanda

2. Mhangura (Cu)

25% yakakwirira yemagetsi / yekupisa conductivity kupfuura Au

3. Ndarama (Au)

Optimal conductivity, corrosion resistance, uye bonding kuvimbika

4. Sirivha (Ag)

Highest conductivity pakati pesimbi

Aluminium Wire

Aluminium Ribhoni

Copper Wire

Copper Ribhoni

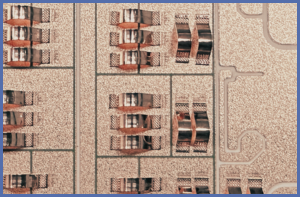

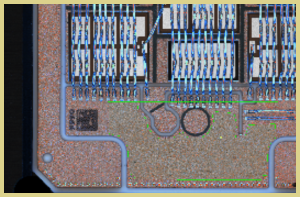

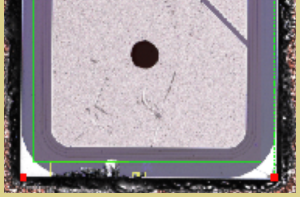

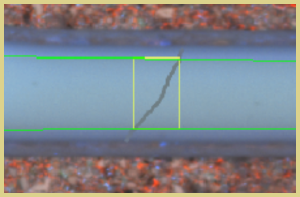

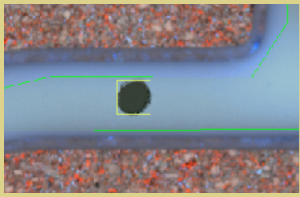

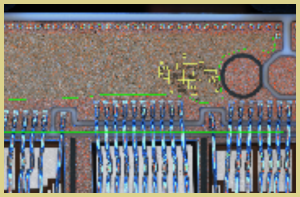

Semiconductor Die Bonding & Wire Bonding AOI

Inoshandisa 25-megapixel indasitiri kamera kuona kufa kubatanidza uye waya yekubatanidza kukanganisa pane zvigadzirwa zvakaita seICs, IGBTs, MOSFETs, uye mafuremu ekutungamirira, kuwana hurema hwekuona hurema hunodarika 99.9%.

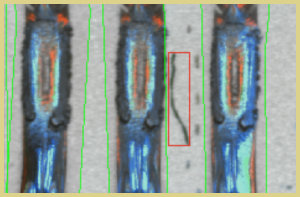

Inspection Cases

Inokwanisa kuongorora kureba kwechip uye flatness, chip offset, tilt, uye kucheka; solder bhora kwete-adhesion uye solder joint detachment; kukanganiswa kwewaya kunosanganisira kureba kana kusakwana, kudonha kwechiuno, waya dzakatyoka, waya dzakashaikwa, waya, kubhenda, kuyambuka loop, uye kureba kwemuswe; kukwana kunamatira; uye simbi splatter.

Solder Bhora/ Zvakasara

Chip Scratch

Chip Kuiswa, Dimension, Tilt Meas

Chip Kusvibiswa / Yekunze Material

Chip Chipping

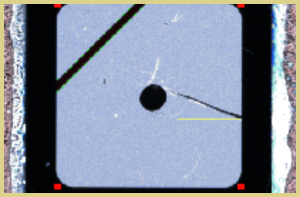

Ceramic Trench Cracks

Ceramic Trench Kusvibiswa

AMB Oxidation

In-Line Formic Acid Reflow Oven

1. Kunyanya tembiricha ≥ 450°C, shoma yevacuum level <5 Pa

2. Inotsigira formic acid uye nitrogen process environments

3. Single-point void rate ≦ 1%, yakazara void rate ≦ 2%

4. Mvura inotonhorera + nitrogen kutonhora, yakashongedzerwa nemvura-inotonhorera system uye kusangana kutonhora

IGBT Simba Semiconductor

Yakawandisa voiding rates muIGBT soldering inogona kukonzeresa kutadza kwecheni-rection kusanganisira kupisa kwekupisa, kuputika kwemechini, uye kukanganisa kwemagetsi. Kudzikisa mitengo yevasina kusvika ku ≤1% kunosimudzira kuvimbika kwechishandiso uye kushanda nesimba.

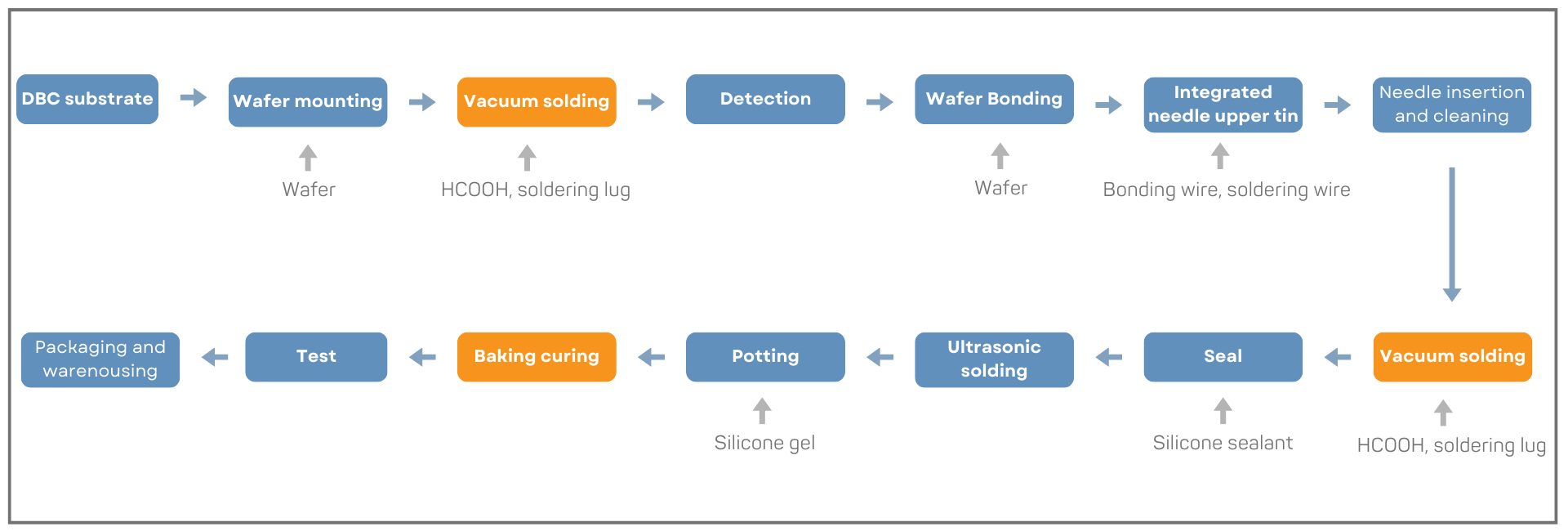

IGBT Production process flowchart